Being an apprentice, I get to work across a lot of different areas and get to learn from great people.

Composites Technician

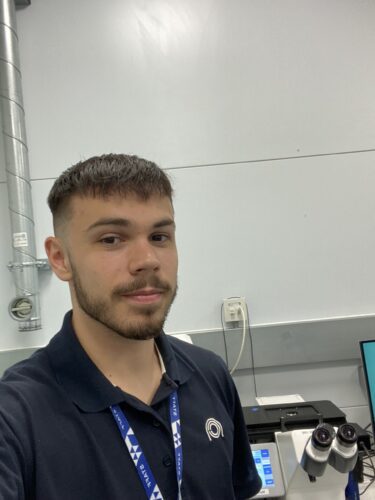

Aidan Church

Composites Technician

Thomas’ job title is Composites Technician at the National Composites Centre

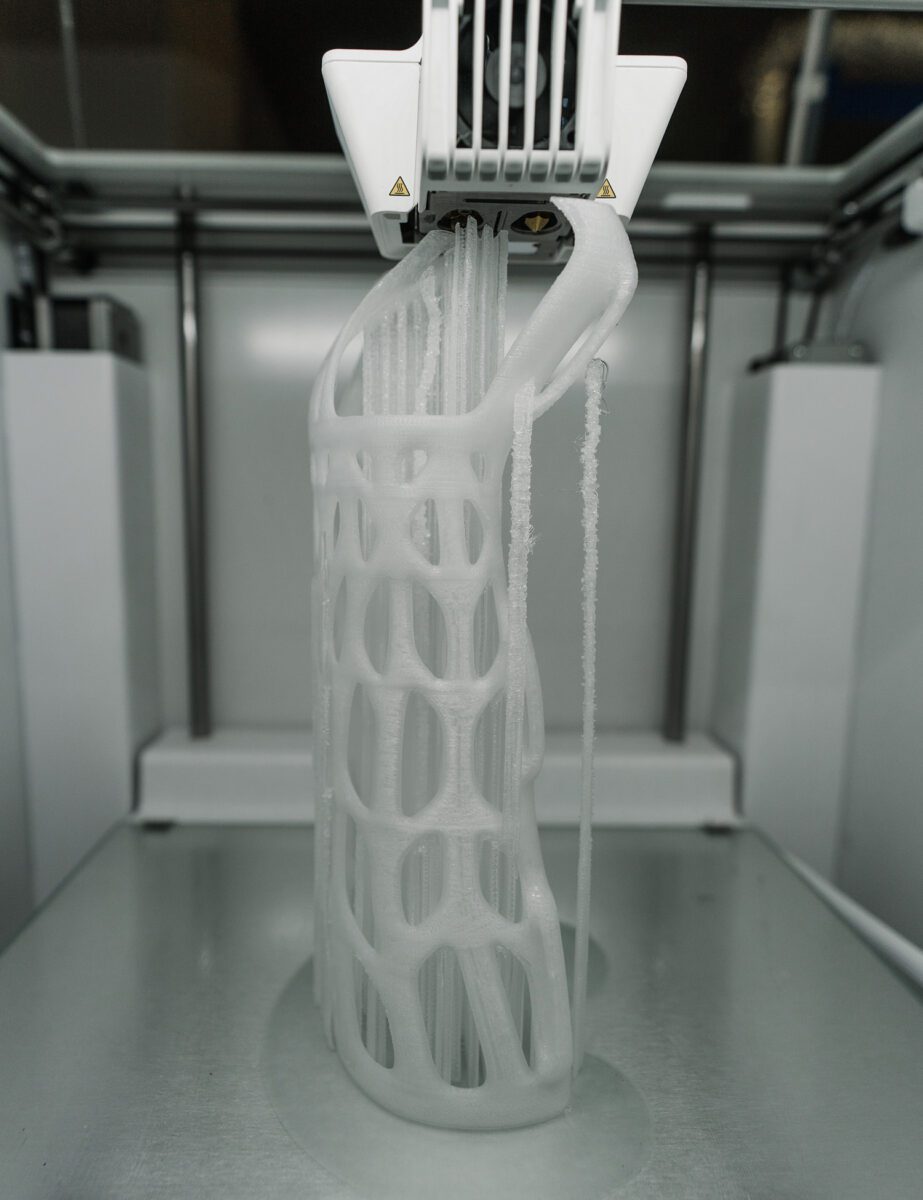

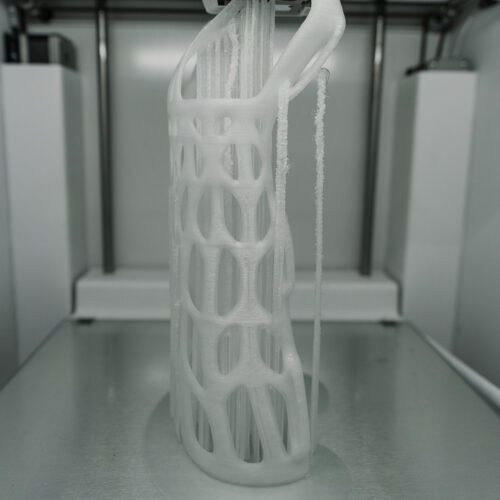

I make composite materials like carbon fibre, glass fibre and Kevlar which are used to make cars and planes. We work with big aerospace brands by helping develop their ideas into parts, which we then test. After they pass our tests, we produce these parts for them. As I am an apprentice, I work across different zones, learning about all the areas. There’s a resin infusion zone, a clean room for what we call ‘pre-preg’ work and non-destructive testing where we test the parts before making them. We’ve also got a machine shop and high value manufacturing where we have bigger machines for manufacturing lots of parts quickly.

Hear more about Thomas' role by watching the video below...

We are a research facility, so big companies like GKN Aerospace, Rolls Royce, Airbus, and other top-vehicle brands come to us with their ideas and we work together with them to develop parts, making them lighter, stronger and more durable.

Being an apprentice, I get to work across a lot of different areas and get to learn from great people.

I like working with lots of people, all different ages, with different experiences, and hearing their stories. They’re good at showing me a task and letting me get on with it. They’re direct and tell me what needs to be done and how to do it and then I get to try it - that works for me, to have the instruction and then being able to crack on with it.

I worked on a big (secret!) project which was great as I worked on it from start to finish with the same team and got to see the whole way through the process. It was really nice, a great accomplishment to complete it, especially as we overcame some challenges along the way. It was an amazing feeling to see it finished.

Don’t be too conscious and not speak out, don’t over think things. People don't really mind what you say so they won’t think anything of it, just ask the question and chat!

Discover what qualifications you’ll need, how much you can earn, and what the next steps are.